Our People Health and

safety

A culture of zero harm is our first priority. We consider it essential that employees and contractors at our sites have the knowledge, skills and equipment needed to perform their jobs safely – and the support of management and co-workers to approach each task the right way.

Within two years of start-up, operations are required to be certified to the OHSAS 18001 health and safety management standard. In Manitoba, external evaluators perform semi-annual audits to confirm ongoing compliance. We also follow the Mining Association of Canada’s Towards Sustainable Mining (TSM) health and safety protocols at operating sites within and outside of Canada. Internal assessments against the TSM protocols are performed annually and third-party verification takes place once every three years.

An integrated management software system supports the process of recording, investigating and tracking all types of incidents and non-conformances across the Company. Since its implementation in 2014, the system has enabled us to conduct more rigorous reviews of high-potential safety risks and put in place appropriate controls.

The Positive Attitude Safety System (PASS) is an important program for driving performance in Manitoba. PASS is based on facilitated discussions at all levels of the organization, to increase each person’s involvement in recognizing and managing workplace risks. PASS includes activities like safety huddles at the start of each shift, “A” logs for recording crews’ safety fixes and improvements, the rating of safe days, and monthly PASS newsletters. Its success is due in part to its strong emphasis on positive reinforcement.

At operating sites, we maintain programs aimed at promoting and maintaining employee health and wellness. For example, in Manitoba, the programs include:

- Fibrogenic dust screening conducted at least twice a year;

- Hearing surveillance tested at least annually; and

- Biological monitoring for workers who may be exposed to lead, cadmium or arsenic as part of their work. At the time of obtaining biological monitoring samples, employees are also counselled on proper respirator fit and use, personal hygiene, working and eating habits, smoking, alcohol and drug intake, and potential sources of metals exposures outside of the workplace.

Constancia is a remote site and many workers travel long distances to work eight- or 14-day rotation shifts. They remain on-site during their shift rotation, staying at company-provided accommodation. There are a variety of health and wellness services and amenities available to them at the camp, including a medical centre, a soccer field and a volleyball court. Constancia employees are offered massage therapy and chiropractor services semi-annually. We also host our own “Olympic Games”, which include chess and table tennis competitions.

Wellness programs, run by employee wellness committees, have been launched at each location. The programs include lunch and learns, walking competitions, newsletter articles and targeted campaigns for common topics like cold and flu, allergy awareness and managing stress. Your Health Matters Here is a place on the corporate intranet for employees to share health and wellness information and to propose corporate donations to health-related programs that are meaningful to them.

2015 PERFORMANCE HIGHLIGHTS

Corporate

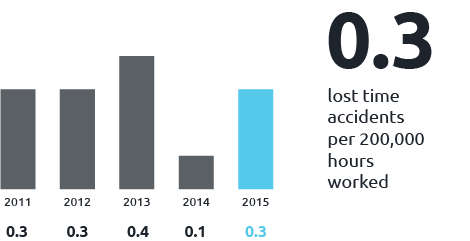

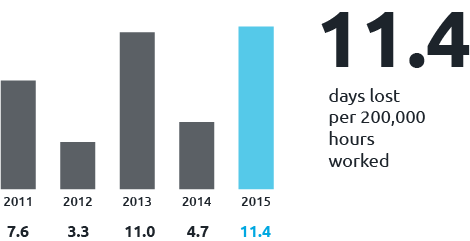

- Our lost time accident (LTA) frequency was 0.3 per 200,000 hours worked, compared to 0.1 in the previous year. Lost time accident severity, which reflects the number of days missed, was 11.4 versus 4.7 in 2014. While performance was not at our record 2014 level, it was still a strong year for safety. The major difference was in the increased number of LTAs in the first half of the year at Constancia, which, combined with fewer hours worked (about half of the previous year), resulted in the significant increase in LTA frequency.

Lost Time Accident Frequency

| Year | Frequency |

|---|---|

| 2011 | 0.3 |

| 2012 | 0.3 |

| 2013 | 0.4 |

| 2014 | 0.1 |

| 2015 | 0.3 |

Lost Time Accident Severity

| Year | Days Lost |

|---|---|

| 2011 | 7.6 |

| 2012 | 3.3 |

| 2013 | 11.0 |

| 2014 | 4.7 |

| 2015 | 11.4 |

Manitoba

- Safety performance was bolstered by a number of new processes and a strong emphasis on potentially serious incidents:

- We introduced the incident cause analysis method (ICAM) for investigating incidents and near misses. ICAM helps determine root causes so that appropriate action can be taken. Twenty-four ICAM investigators were trained, including management and union members.

- Department heads held regular “Safety Stand-Downs” with their crews to discuss pressing safety issues (incidents or trends).

- The metallurgical surface departments introduced the “Take Five” safety card system. In a process similar to the five-point safety card system used in the underground mines, workers identify hazards on a Take Five card before starting a new activity. The system is credited with helping drive noticeable improvement in the safety performance of the zinc plant and Flin Flon mill.

Peru

- The start of 2015 brought substantial change to the Peru team with the transition from a construction project to operations. Safety performance slipped in the first half of the year, and included two serious close calls, which prompted an increased focus on safety controls, procedures and communications. Through a series of safety talks, we reinforced basics like pre-work job safety analyses. To help nurture a safety culture, the Peru management team also mandated weekly safety audits conducted by department heads and started weekly, one-hour safety chats with supervisors and contractors. These actions contributed to noticeable improvement in the second half of the year.

- We also had to address transportation safety issues related to the large number of trucks hauling concentrate from the mine to the port at Matarani. See the Constancia case study to learn more.

Arizona

- Despite the significant drilling campaign, there was only one reportable incident in 2015, related to an ergonomic issue.

- Most of the year was spent preparing health and safety systems and processes to be scaled up for construction. This included:

- Developing an Environment, Health and Safety Policy based on the Hudbay corporate policy and local health and safety standards;

- Establishing a joint occupational health and safety committee;

- Introducing the “Take Five” safety card system;

- Establishing safety Golden Rules for high-risk tasks;

- Installing “lone worker” GPS tracking system for remote workers (surveyors, geologists, etc.); and

- Implementing an online material safety datasheet system (now called an SDS system).

More on Health and Safety

One of our summer students in Manitoba developed an innovative Stress Less campaign, meeting with work crews to discuss stress and mental health, and to present wellness and coping strategies. She also ran a Stress Less challenge in which participants completed weekly questionnaires about their physical activity and wellness for a chance to win prizes.

In Peru, we offered a parenting skills course to employees and their spouses. At the end of the session, one-on-one counselling was available free of charge to those who wanted it.